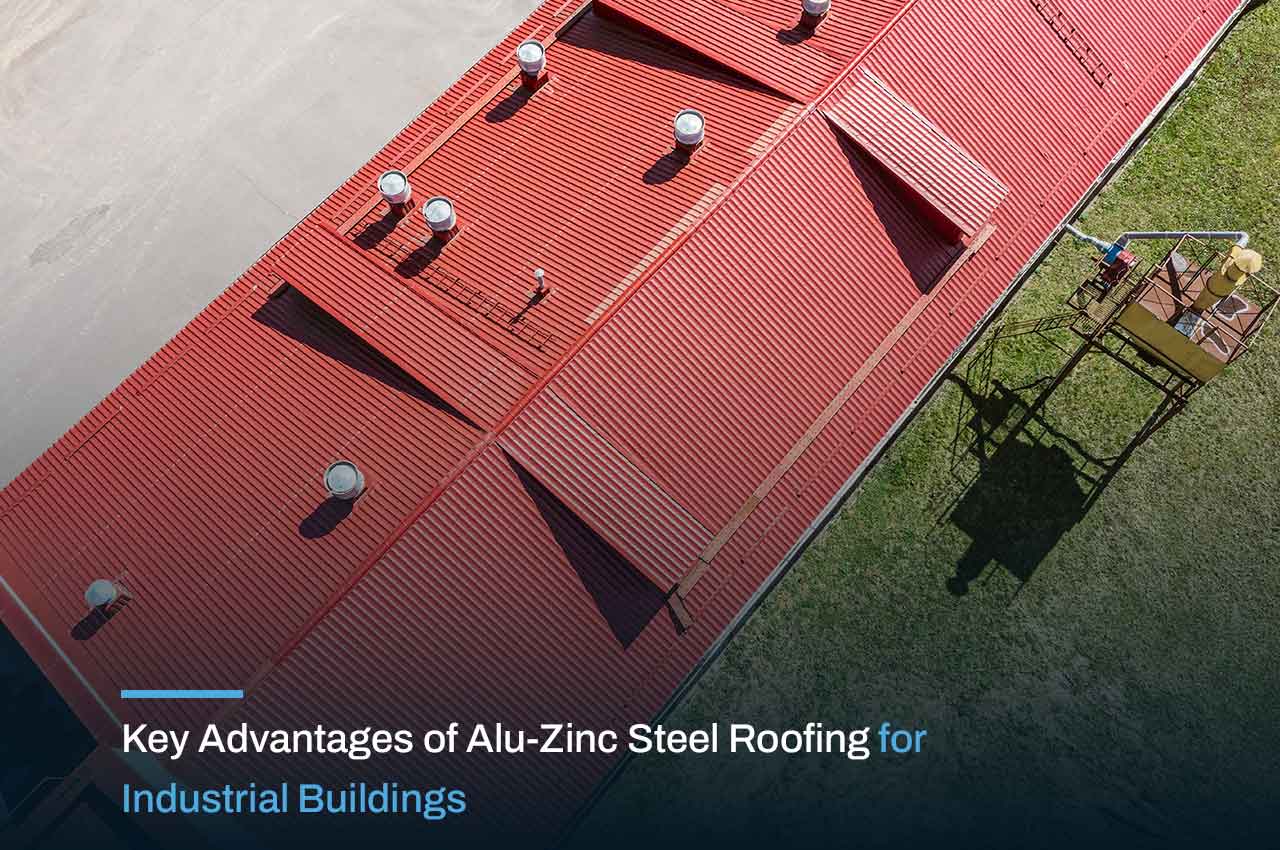

The development of steel roofing continues to make significant advancements. Aluzinc steel, also known as Galvalume, is one of the most reliable and highest-performance materials available for your roof. In choosing a roofing material for industrial buildings, durability and cost-effectiveness, as well as maintenance, are major factors. It provides all of these advantages, and therefore it’s the best choice to use for industrial buildings, warehouses and large commercial buildings.

Aluzinc, or Galvalume, is a kind of coated steel, created when sheets of steel are immersed in a blend of aluminium, zinc and silicon. It contains approximately 55% aluminium, 43.4% zinc and 1.6% silicon. Its protective qualities make it resistant to corrosion, rust and other forms of environmental degradation, while also retaining the structural properties of the steel.

Aluzinc steel has superior bonding strength with steel due to its aluminium- and zinc-coated surface, helping to protect the underlying steel from corrosion over an extended period. Compared to conventional galvanised steel products, it does not oxidise or corrode easily. Therefore, under typical industrial conditions where steel would typically experience corrosion, Galvalume will provide an almost maintenance-free roof lifetime.

For the majority of Aluzinc steel manufacturers, in addition to manufacturing standard-sized sheets, custom-made panels specifically for roofing, siding, etc. are available. Many panels also have factory-painted finishes that provide visual enhancement and are functional in nature. This adds to the advantages of Alu-zinc steel for industrial buildings.

A major advantage of Aluzinc steel is that its design reduces the volume of required maintenance. Roofs in industrial buildings are frequently exposed to extreme weather as well as a range of corrosive chemicals. Examples of traditional roof coverings are galvanised steel, asphalt and concrete, which can become corroded, cracked or warped, leading to the possibility of having to frequently perform repairs.

With Aluzinc steel roofing, this problem is eliminated due to the Galvalume coating’s superior corrosion protection. This advanced coating reduces the possibility of leaks and damage to the roofing structure. Studies have shown that Alu-zinc steel roofing can provide 40–60 years of service with very little maintenance, while traditional galvanised roofing will often require repairs or replacement every 15–20 years.

The long-term cost savings associated with industrial building roofs are significant, as maintenance workers will require fewer labour hours for panel repairs, and industrial operations will experience fewer disruptions caused by roof-related problems. Because of this, galvalume offers factories, warehouses and other large-scale facilities a high-value investment over the long term.

1. Corrosion resistant: Galvalume outperforms traditional galvanised steel by providing a level of protection against rust or corrosion approximately ten times greater than that of standard galvanised steel.

2. Longer lifespan: The combination of steel strength and Galvalume coating ensures roofs last for decades. This longevity is a major advantage it offers to industrial facility owners.

3. Strength and Durability: Aluzinc steel is known for its high strength, although it is light in weight; it can resist wind uplift, heavy rain and vibration from machinery, which makes it a great material choice for industrial buildings, particularly for those with large spans.

4. Design Flexibility and Aesthetics: Modern Aluzinc steel manufacturers offer panels in various profiles and colours. This allows industrial buildings to combine functionality with a professional and visually appealing appearance.

Roofing materials for commercial and industrial buildings need to be affordable and provide long-term service without requiring much maintenance. Aluzinc steel, which is also called galvalume, meets this criterion. Several advantages of Alu-zinc steel are a longer lifespan, corrosion resistance and low maintenance costs.

By partnering with a reliable and reputable Aluzinc manufacturer, you will be able to choose the most suitable panels for your project, ensuring cost-effective, long-lasting roofing systems.

Q. Is Galvalume the same as Aluzinc steel?

A. Yes, Galvalume is the commercial name commonly used for Aluzinc steel. It refers to steel coated with an aluminium-zinc alloy that provides enhanced corrosion protection compared to galvanised steel.

Q. Does Aluzinc steel roofing help with energy efficiency?

A. Alu-zinc steel reflects heat effectively, helping reduce roof surface temperatures. This improves energy efficiency and lowers cooling costs in industrial buildings, especially in hot climates.

Q. What is the main advantage of Aluzinc steel for industrial buildings?

A. The biggest advantage alu-zinc steel offers is long-term durability with low maintenance. It resists rust, withstands harsh weather, and maintains structural strength for decades in demanding industrial environments.