In today’s construction landscape, choosing the right material for roofing and cladding is not just about functionality; it’s about lasting performance, aesthetics and sustainability. That’s why Pre-Painted Galvanised Steel (PPGI) has become the preferred choice for modern architects and builders. From superior durability to design flexibility, here are the key advantages of using colour-coated steel sheets and why choosing a trusted Pre-Painted Galvanised Steel Manufacturer like us ensures you get lasting quality.

PPGI, or Pre-Painted Galvanised Iron/Steel, starts with a galvanised substrate (a zinc-coated steel base) that’s then factory-primed and top-coated before any forming or fabrication. This coil coating ensures a precise, uniform, and robust finish, far superior to post-painting.

In contrast, regular galvanised or post-painted steel lacks the same uniformity, adhesion, and longevity that PPGI provides, making it less suitable for demanding roofing and cladding applications.

PPGI coatings, especially when paired with zinc-aluminium or zinc-aluminium-magnesium alloys, resist corrosion much longer than conventional galvanising. In harsh or humid environments, they deliver extended protection.

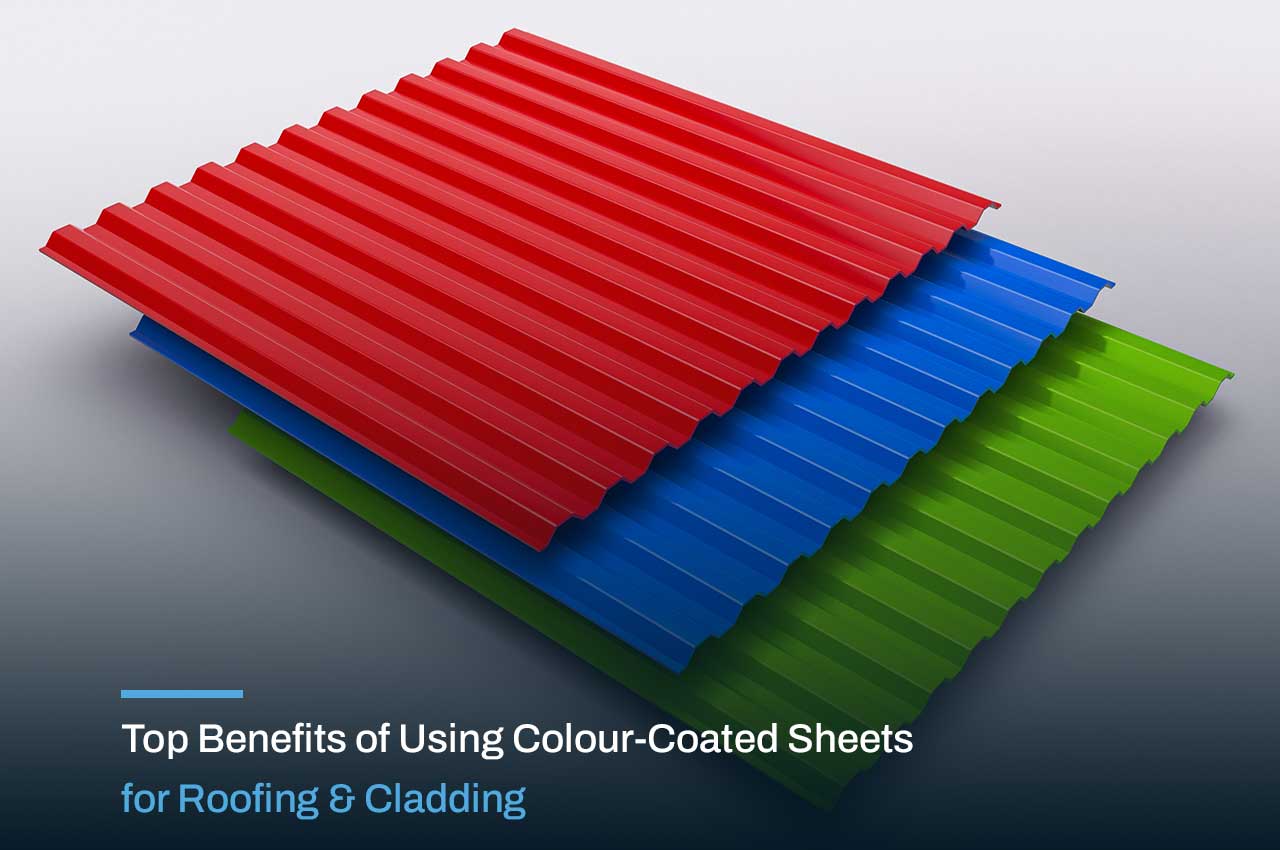

With options ranging from bold hues to textured and matte finishes, PPGI enhances the visual appeal of buildings. The coil coating process ensures consistent, high-quality surfaces across large runs.

Colour-coated sheets retain the inherent strength of steel while remaining lighter than many alternatives. They can be engineered in varying thicknesses and profiles, such as trapezoidal, hi-rib, tiled, or sinusoidal, to meet structural and aesthetic demands.

Reflective PPGI finishes, especially light or “cool” colours, can significantly reduce building energy use. Some metal roofing coatings lower energy consumption by up to 40% in summer and 15% in winter. Additionally, proper insulation combined with colour-coated sheets leads to noteworthy energy savings.

Steel is one of the most recycled materials globally, and PPGI sheets are fully recyclable, helping reduce construction waste and carbon footprint.

PPGI’s smooth, coated surface means dirt and debris are less likely to stick. Roofing with natural weather exposure may need minimal upkeep, while sheltered areas benefit from simple, infrequent cleaning.

PPGI’s metallic base and fire-resistant coating make it non-combustible, ideal for regions prone to forest fires or extreme weather conditions.

We exemplify reliability in PPGI supply. With in-house two-coat, two-bake coil-coating technology, a range of profiles (trapezoidal, hi-rib, sinusoidal, tiled), and strong certifications (ISO 9001, 14001, 45001), we deliver both aesthetic and structural excellence. Our “Colour Strong” brand emphasises fire, wind, and corrosion resilience coupled with thermal benefits.

Conclusion

Using Pre-Painted Galvanised Steel brings together the best of form and function, long-lasting durability, visual versatility, energy efficiency, and minimal maintenance. And when sourced from a reputable Pre-Painted Galvanised Steel Manufacturer like us, we ensure consistent quality backed by advanced technology and certifications.

Whether you’re working on residential projects, industrial buildings, or architectural facades, PPGI delivers unmatched performance, making it a top-tier choice for roofing and cladding solutions.

FAQs

Q. How long does Pre-Painted Galvanised Steel last in roofing and cladding applications?

A. With proper installation and maintenance, high-quality PPGI sheets can last 20 to 40 years or more, depending on the coating system, environment, and exposure conditions.

Q. Can Pre-Painted Galvanised Steel withstand extreme weather conditions?

A. Yes. PPGI sheets are designed for durability; they resist corrosion, fire, UV radiation, heavy rainfall, and high winds, making them suitable for diverse climates.

Q. Why should I choose a reputed Pre-Painted Galvanised Steel Manufacturer?

A. A trusted manufacturer ensures consistent coating quality, adherence to international standards, and availability of varied colours, profiles, and finishes, guaranteeing both performance and aesthetics for your project.